Excursion for MS students of the National Research University ‘Moscow Power Engineering Institute’

On 8 October 2021, Izolyator hosted an educational excursion for graduate students of the Department of Physics and Technologies of Electrical Materials and Components of the Institute of Electrical Engineering and Electrification of the National Research University ‘Moscow Power Engineering Institute’.

Department of Physics and Technologies of Electrical Materials and Components of the Institute of Electrical Engineering and Electrification of the National Research University ‘Moscow Power Engineering Institute’ (Dept. of PTEMC IEE MPEI) graduates specialize in research of electrical materials and devices, insulating equipment and cabling products. National Research University ‘Moscow Power Engineering Institute’ is the one from the largest technical universities of Russia. It provides the specialist’s training and scientific research in the field of energetic, electrical engineering, radio electronics, computer engineering.

Department of Physics and Technologies of Electrical Materials and Components of the Institute of Electrical Engineering and Electrification of the National Research University ‘Moscow Power Engineering Institute’ (Dept. of PTEMC IEE MPEI) graduates specialize in research of electrical materials and devices, insulating equipment and cabling products. National Research University ‘Moscow Power Engineering Institute’ is the one from the largest technical universities of Russia. It provides the specialist’s training and scientific research in the field of energetic, electrical engineering, radio electronics, computer engineering.

In accordance with the work plan of the department, the class was given by the head of the Dept. of PTEMC IEE MPEI, CEO of Izolyator, Dr. Alexander Slavinsky. The class was assisted by Artem Semyonov, a postgraduate student of the Dept. of PTEMC IEE MPEI, Design Engineer at the R&D center of the Izolyator Production Complex.

Before the start of the educational excursion, undergraduates were instructed on labor protection, which is mandatory when visiting a production facility.

Instructing the students of the MPEI master's program on labor protection before the educational excursion to Izolyator

Instructing the students of the MPEI master's program on labor protection before the educational excursion to Izolyator

The class began with an acquaintance with the centuries-old history of the Izolyator plant in the corporate museum. The students learned about the milestones in the formation and development of the enterprise and the role that the plant has always played in creating a powerful and modern energy system in Russia, in international cooperation with power engineers from other countries.

Acquaintance with the history of Izolyator plant

Acquaintance with the history of Izolyator plant

The historical journey was complemented by a visit to the exposition, organized in a specially created exhibition space and dedicated to the 125th anniversary of the Izolyator plant. The exposition presents documentary and material evidence of the era, in the parallels of past events and the present day, the sources and continuity of the glorious traditions of the enterprise's staff are revealed.

Seeing of the exposition dedicated to the 125th anniversary of the Izolyator plant

Seeing of the exposition dedicated to the 125th anniversary of the Izolyator plant

Then, the master students started a step-by-step visual acquaintance with the technology and equipment of the production of modern high-voltage bushings with solid internal RIP and RIN insulation.

MPEI undergraduates are getting acquainted with the machining of parts on numerically controlled machines

MPEI undergraduates are getting acquainted with the machining of parts on numerically controlled machines

Tour of the insulation making shop: internal and external insulation of high-voltage bushings

Tour of the insulation making shop: internal and external insulation of high-voltage bushings

All phases of the production process, the work of each section and the sequence of technological modes were accompanied by detailed explanations and comments by Alexander Slavinsky.

At the assembly station of bushings of voltages from 252 to 1200 kV

At the assembly station of bushings of voltages from 252 to 1200 kV

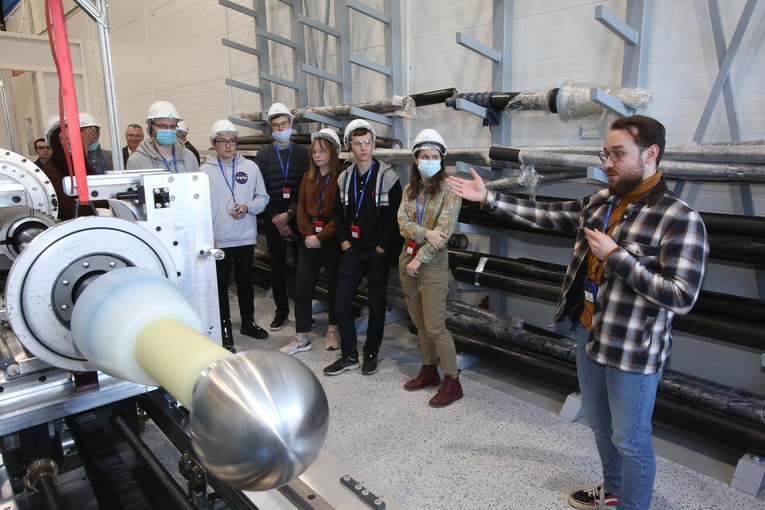

Acquaintance with the equipment of the test center

Acquaintance with the equipment of the test center

Thus, the excursionists had a holistic view of the technological cycle of high-voltage bushings production: from the manufacture of metal parts for future bushings and the preparation of insulating components to testing assembled products and storing finished products to be shipped to customers later.

The finished goods packaging station

The finished goods packaging station

Also, the undergraduates visited the R&D center, where the development of innovative high-voltage insulation equipment and advanced development works are underway.

The next object of the study tour was the Izolyator-AKS high-voltage cable accessories plant.

Alexander Filippov, a post-graduate student of the Dept. of PTEMC IEE MPEI, Production Process Engineer introduced the students to the latest technological equipment and products of the enterprise — cable joints and outdoor terminations, cable connectors for voltages from 126 to 252 kV for cable cross-sections up to 2500 mm².

Izolyator-AKS cable accessories are manufactured on the most modern and unparalleled injection molding machines.

Acquaintance with the operation of an injection molding machine for the manufacture of control elements for cable accessories

Acquaintance with the operation of an injection molding machine for the manufacture of control elements for cable accessories

All manufactured cable accessories undergo acceptance tests in own testing laboratory equipped with unique equipment.

In the cable accessories testing laboratory

In the cable accessories testing laboratory

As a result of training at Izolyator, master students acquired systematic and solid knowledge of the development and production of advanced high-voltage insulation equipment that meets the highest international standards.

Educational tours of production for students in vocational and higher education institutions have long become a traditional and a very important activity of Izolyator. In this way, the company contributes to the formation of future industry professionals who will have to research and implement even more advanced insulating materials and design solutions, create innovative equipment that ensures the most efficient functioning of advanced electric power systems.