Working Meeting With SuperOx Representatives

On 4 February 2020, a working meeting with SuperOx representatives took place at Izolyator plant.

Since 2006, SuperOx has been developing the technology of high temperature superconductors (HTS), producing Russian-made HTS wires and power equipment based on them using its own technology. In 2014, the Government of Moscow initiated implementation of a project of superconducting fault current limiter (SFCL) to ensure high reliability of power supply of the city. Superconducting fault current limiter is developed and manufactured by SuperOx. At the end of 2017, by the decision of the Ministry of Energy of Russian Federation the SFCL received the status of a national project.

The first part of the meeting was devoted to the discussion of a significant event that resulted from a great joint work — the ceremonial commissioning of the superconducting fault current limiter, which took place in December 2019 in Moscow at the Mnevniki electrical substation of the United Energy Company.

The device is designed, manufactured, delivered and installed by SuperOx.

Within the framework of this project, Izolyator specially designed, manufactured and successfully tested the world's first 220 kV Liquid nitrogen — Air high-voltage bushings with capacitive regulation of the electric field. The bushings with solid internal RIN insulation can withstand temperatures ranging from –200 ºС at the bottom to +10 ºС at the top of the structure.

SuperOx superconducting fault current limiter with Izolyator high voltage bushings at the Mnevniki electrical substation of the United Energy Company in Moscow

In the second part of the meeting, the parties discussed the organizational and technical aspects of the upcoming work on the creation and joint testing of high-voltage bushings for new fault current limiter based on technology of high temperature superconductors.

Working meeting at Izolyator plant with SuperOx representatives

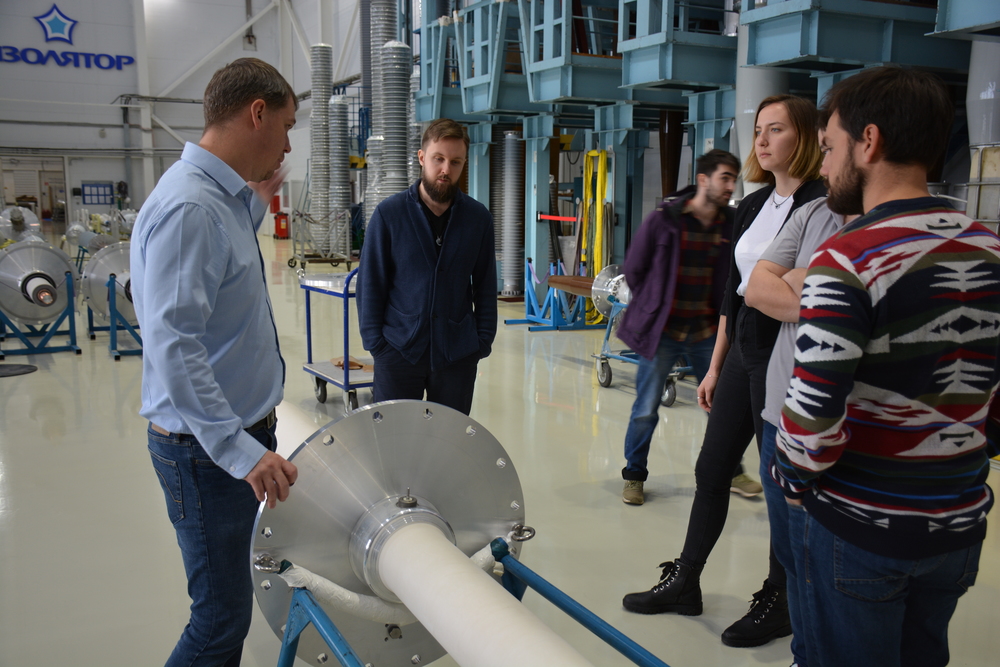

A tour of the production took place, where the representatives of SuperOx got acquainted with the technological cycle of manufacturing of modern high-voltage bushings, and first of all — bushings with RIN insulation, as most advanced and promising.

SuperOx representatives are getting acquainted with the technological cycle of manufacturing of bushings with RIN insulation at Izolyator plant

Ahead — joint testing of Izolyator high voltage bushings, specially developed for the new SuperOx new fault current limiter based on technology of high temperature superconductors

Thus, the past meeting marked the beginning of a new stage in the successful and fruitful cooperation of the two enterprises.